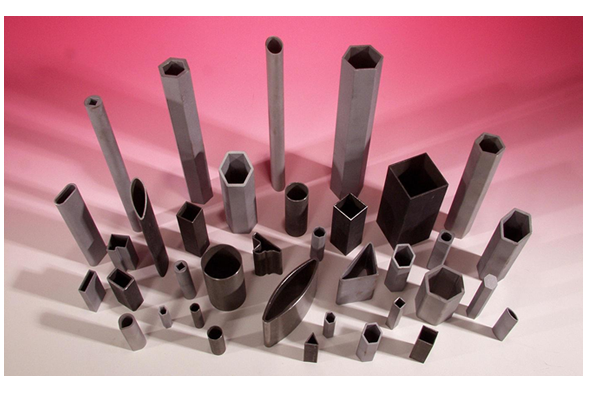

Presentation

Aerospace applications

Quality

Osborn Metals has developed a strong quality and improvement culture to offer its customer best products and services with optimized processes and solutions.

EN SAVOIR +Actualités

En direct du “Tube & Wire” - Düsseldorf

Laetitia, Andreas et Arnaud sont fin prêts à vous recevoir sur notre stand (Hall 1 E 36) du Salon Tube & Wire à Düsseldorf. Venez nous (...)

Osborn Metals avec le Schanzer Racing Electric

Schanzer Racing Electric est une association à but non lucratif composée de plus de 60 étudiants de diverses facultés et de l’équipe Formula Student (...)

Tubes en 826M40 disponibles !

Nous avons réussi à étirer nos premiers tubes en 826M40. C’est un matériau surprenant par ses capacités d’écrouissage ainsi que par la complexité des (...)

Les solutions de parachèvement clés en main chez Osborn Metals

Oui, chez Osborn Metals nous sommes spécialistes de l’étirage à froid de tubes, barres et profils spéciaux. Mais sachez que nous pouvons proposer un (...)